HYDROGEN SUPPLY CHAIN

Hydrogen Energy Supply Chain Pilot Project between Australia and Japan

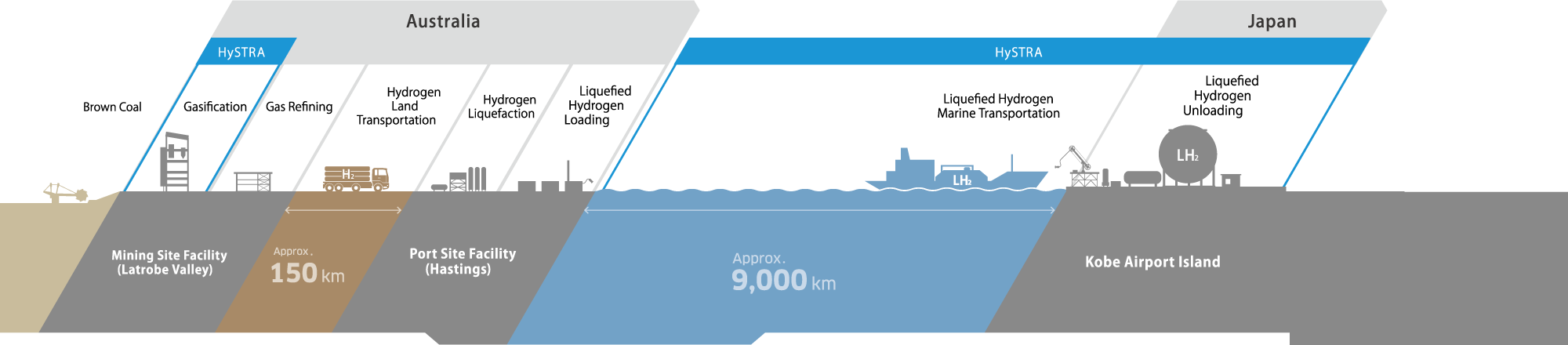

In 2020-2021, the pilot project will demonstrate brown coal gasification and hydrogen refining at Latrobe Valley in Australia, hydrogen liquefaction and storage of liquefied hydrogen at Hastings, marine transportation of liquefied hydrogen from Australia to Japan and unloading of liquefied hydrogen in Japan.

- brown coal gasification technology

- technology of long distance transportation of mass liquefied hydrogen

- liquefied hydrogen loading and unloading technologies

Brown Coal

An abundant unused resource lying under the earthʼs surface, this is low rank coal, brown coal.

Approximately half of the worldʼs total coal resources is brown coal.

However, it is relatively heavy and bulky, but low calorie due to its extremely high moisture content. As it runs the risk of igniting spontaneously upon contact with air, it is not suitable for transportation and storage in its raw form. Thus, it is limited to on-site applications.

Can we mass-produce affordable and clean hydrogen from this unused resource?

Our journey starts here.

Reserves

Loy Yang Complex in Latrobe Valley. It is about 6,000 ha, including the power generation facility.The brown coal reserves in Australia have the potential to meet Japanʼs electricity demand for several hundred years.

Gasification Facility

Brown coal has a high moisture content and unstable qualities. The gasification process therefore needs to resolve various technological hurdles in order to realize mass production in the future.

Gas Refining Facility

During the process of extracting hydrogen from syngas, it is possible to separate and capture carbon dioxide. This will reduce greenhouse gas emissions, despite the energy being derived from fossil fuels.

Liquefaction / Loading Facility

-253℃, 1/800

By cooling hydrogen down to a cryogenic level of -253℃, it is converted from gas into liquid and reduces in volume by 1/800. Such reduction in volume allows for more efficient transportation and distribution of more hydrogen.

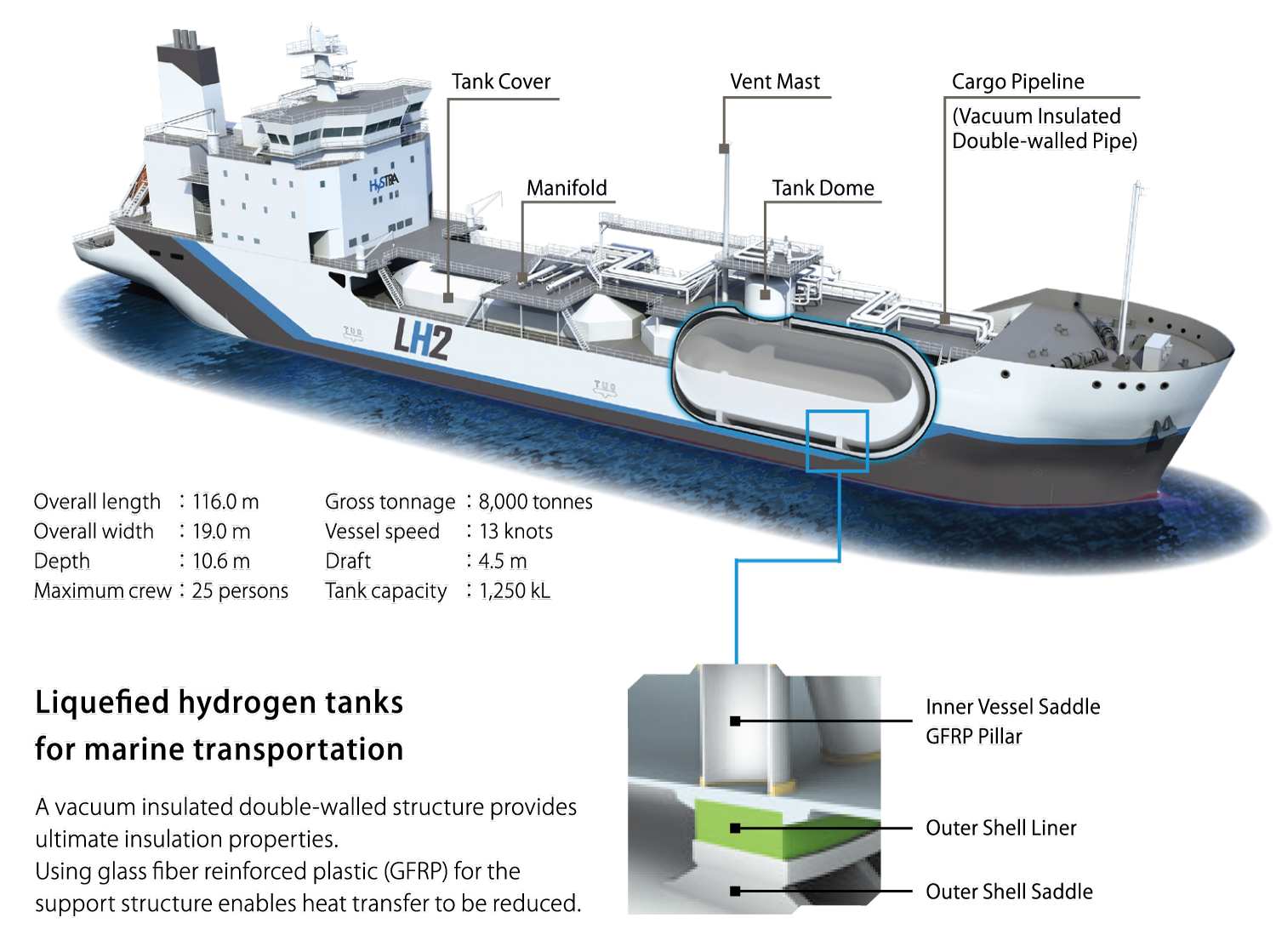

Liquefied Hydrogen Carrier

Technology to maintain a temperature of -253℃ whilst traversing the Earth

Using existing technologies for construction of LNG marine carriers and for land transportation and storage of liquefied hydrogen, a new cargo containment system with cryogenic temperature and accumulated pressure to specifically transport liquefied hydrogen on a marine carrier has been developed. Our aim is to establish technology for safe and efficient transportation of mass volumes of hydrogen.

Storage and Unloading Facilities

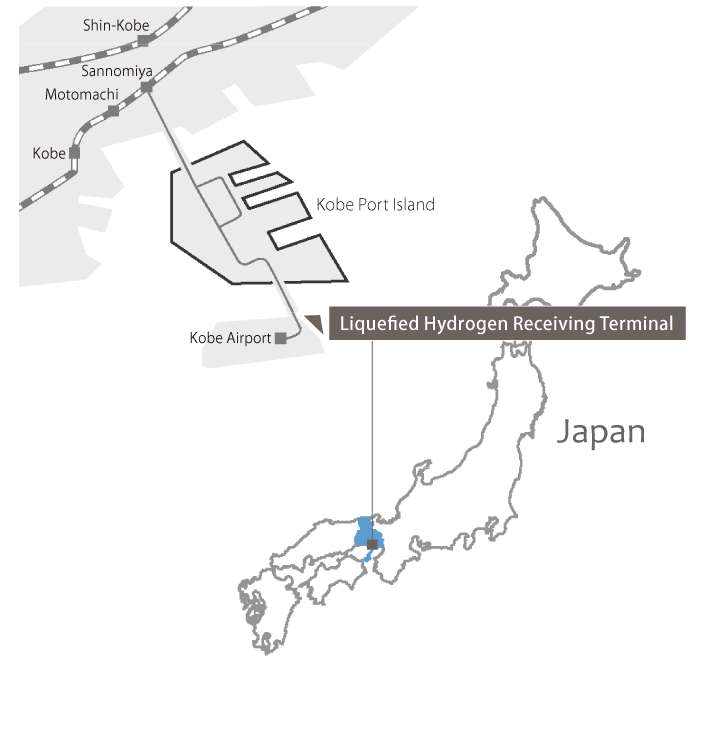

Liquefied Hydrogen Receiving Terminal in Japan

The liquefied hydrogen marine carrier arrives after a journey of around 9,000 km. A loading arm system unloads the hydrogen from the carrier into an on-land liquefied hydrogen storage tank, whilst maintaining a temperature of -253℃. This is the first new energy terminal in Japan.